In a tent in the Surucuá community in the Brazilian Amazonian state of Pará, Jhanne Franco teaches 15 local adults how to make chocolate from scratch using small-scale machines instead of grinding the cacao beans by hand. As a chocolatier from another Amazonian state, Rondônia, Franco isn’t just an expert in cocoa production, but proof that the bean-to-bar concept can work in the Amazon Rainforest.

“[Here] is where we develop students’ ideas,” she says, gesturing to the classroom set up in a clearing in the world’s greatest rainforest. “I’m not here to give them a prescription. I want to teach them why things happen in chocolate making, so they can create their own recipes.”

The training programme is part of a concept developed by the nonprofit Amazônia 4.0 Institute, designed to protect the Amazon Rainforest. It was conceived in 2017 when two Brazilian scientists, brothers Carlos and Ismael Nobre, started thinking of ways to prevent the Amazon from reaching its impending “tipping point,” when deforestation turns the rainforest into a dry savanna.

Their solution is to build a decentralized bioeconomy rather than seeing the Amazon as a commodity provider for industries elsewhere. Investments would be made in sustainable, forest-grown crops such as cacao, cupuaçu and açaí, rather than cattle and soy, for which vast swaths of the forest have already been cleared. The profits would stay within local communities.

A study by the World Resources Institute (WRI) and the New Climate Economy, published in June 2023, analysed 13 primary products from the Amazon, including cacao and cupuaçu, and concluded that even this small sample of products could grow the bioeconomy’s GDP by at least $8 billion per year.

To add value to these forest-grown raw materials requires some industrialization, leading to the creation of the Amazonian Creative Laboratories (LCA). These are compact, mobile and sustainable biofactories that incorporate industrial automation and artificial intelligence into the chocolate production process, allowing traditional communities to not only harvest crops, but also process, package and sell the finished products at premium prices.

The logic is simple: without an attractive income, people may be forced to sell or use their land for cattle ranching, soy plantations, or mining. On the other hand, if they can make a living from the forest, they have an incentive to stay there and protect it, becoming the Amazon’s guardians.

“The idea is to translate this biological and cultural wealth into economic activity that’s not exploitative or harmful,” Ismael Nobre says.

Life-changing factories

After years of planning, the first biofactory was set up at the end of September 2023 in Surucuá, a traditional community in the Tapajós-Arapiuns Extractive Reserve, next to the Tapajós River. Resembling a tent, it’s a geodesic dome that can easily be assembled and dismantled in days, and is fully powered by 60 solar panels, keeping running costs low.

Inside the factory, the equipment hums as it roasts cacao beans, the rich scent of chocolate lingering in the air. There are two zones inside: a small-scale machine room for cooking the chocolate, and another for preparing and storing it.

Franco walks around the compact room, explaining how the oven is equipped with temperature sensors to ensure consistent roasting and how all the machines are automated to make the production as user-friendly as possible.

“You configure your recipe step-by-step in the system, and this system will send information to the equipment that will carry out the entire process without you having to remember it,” Franco says. “It will notify you when you have to add the ingredient to the recipe that you previously programmed.”

In the storage room, fridges brim with the students’ creations of chocolate mixed with local fruit, and cupulate, a fruity, chocolate-like product made from cupuaçu, a close relative of cacao. Franco hands me a bar made by a student, calling it “one of the best chocolates I’ve ever eaten.” It’s mixed with a local forest spice — the exact one is a closely guarded secret — that gives it a spicy cinnamon-like kick.

“We came up with product ideas that I didn’t even know about and that when I tried them I thought they were fantastic,” Franco adds.

The community members can print their own designs on the chocolate, such as cultural symbols or emblems. They’re also taught during the daily classes how they can eventually sell their products to wider markets and comply with food safety regulations. Everyone in the community that Mongabay speaks to expresses the same thing: excitement for the new opportunities the initiative can bring, especially the new livelihood options besides growing cassava, their main economic activity.

“It’s been a great learning experience to know and value much more of our biodiversity and local products,” Mariane Souza Chaves, a community member who works in agriculture, tells Mongabay. “We used to throw away cupuaçu seeds, and now we’re making cupulate with it.

“It generates income for families and improves the quality of life, food security and sovereignty for families here,” she adds. “It’s an alternative income [incentive] for young people to stay here and preserve our cultural knowledge.”

Although the project is still in its early days, it’s taken months to get to this point. Amazônia 4.0 visited several communities in the rainforest and worked with them to create the biofactory concept. The nonprofit invited 13 leaders of Indigenous, riverine, extractivist and Afro-Brazilian quilombola communities to São Paulo, for a week spent visiting chocolate factories to see the entire production process from start until “that moment when the consumer pays the highest price for the finished product,” Ismael Nobre says.

“This is part of our method of developing things with communities in the Amazon. We don’t develop things in our heads and take them there as a magic formula that says, ‘Look, this will be good for you,’” he says. “All the work is done hand in hand and using their local knowledge while understanding that there is more beyond the world they live in, which is the world of high technology.”

Once Franco has delivered all the training by January and the community fully understands the production process and how to operate the machines, the biofactory will be dismantled, loaded onto a boat, and taken to the next riverine or quilombola community within the state of Pará.

In the new location, over the course of a few weeks, the community will receive the same training. Some equipment, all of which has been donated to Amazônia 4.0, will be left at Surucuá so the community can carry on making chocolate and cupulate after the biofactory has gone.

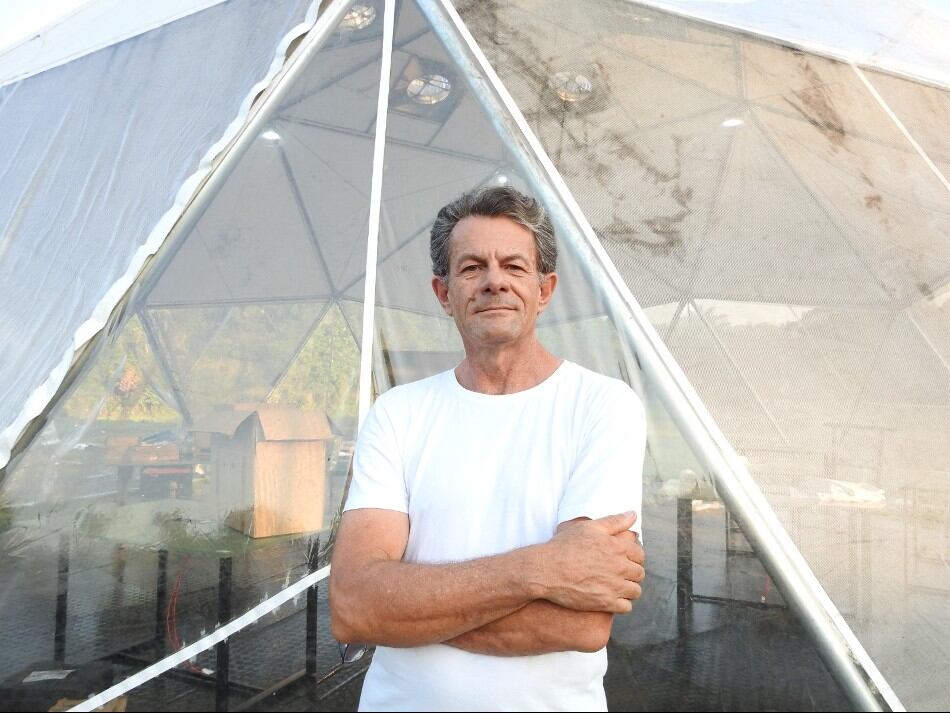

In the factory, we’re joined by Francisco Maia, who helped set up the dome in September and documents all the steps of the project for Amazônia 4.0. Originally from São Paulo, he was part of the team that brought the biofactory from the city to Surucuá, a five-day drive followed by a six-hour boat trip down the Tapajós River, a huge tributary of the Amazon that’s up to 16 kilometers (10 miles) wide in some places.

The project has been a learning curve, Maia says. For example, they learned early on that they needed better air-conditioning in the factory to keep it cool in the Amazonian heat; a steady temperature is critical for the chocolate-making process, as variations can alter the taste. All these discoveries will help improve the success of the project in the next community.

“We’re the guinea pigs,” Maia says. “What will happen in the other communities, we don’t know. They’re all different.”

Building a ‘new way of living’

The Amazon is the largest producer of cacao in Brazil, where the raw material sells for around 10 reais ($2) per kilogram (about 93 cents a pound), Ismael Nobre says.

At the other end of the production chain, “A kilo of fine chocolate costs 200-300 reais,” $41-$61, or about $18.60-$27.70 per lb. “That’s a value-added of about 2,000% or more,” Ismael Nobre says. If these profits could be kept within the communities that make the premium products, they would drastically increase local incomes and provide more incentive to protect the land.

Other Amazonian products, such as the açaí berry, support more than 350,000 people in Pará alone and offer a much higher income than work in livestock ranching or logging, activities associated with rampant deforestation.

Amazônia 4.0 has plans to roll out more biofactories that can also produce gourmet oils and Brazil nuts, another multimillion-dollar industry. “This inflow of resources will generate a chain of economic transformation,” Ismael Nobre says.

Maia and I take shelter from the sizzling midday sun in the air-conditioned biofactory. It’s the dry season in the Amazon, and this year has brought a prolonged drought, the result of a climate that’s changing in unpredictable ways and could spell disaster for the rainforest. Yet there’s hope. “We’re here now in the middle of the storm, but we’re doing something good,” Maia says, looking around the biofactory. “It’s a new way of living.”

- Reproduced with kind permission from Mongabay.com