A 2024 research study published in Food Chemistry identifies the transformative power of artificial intelligence (AI) in the food industry. Undertaking a review of the technology, the researchers find AI can provide advantages to food quality, safety and supply chain efficiency. AI innovations are also expected to revolutionise sustainability and efficiency in the broader industry. However, tackling transparency, data privacy and cost integration concerns is vital to encouraging AI adoption.

The broader integration of AI and big data in the food industry is significant, valued at $6.86 billion in 2022 and projected to reach $ 269.92 billion by 2032, according to Emergen Research. In a 2024 blog, consulting firm Deloitte referenced a study that indicates the uptake of AI in the F&B will grow at an annual rate of 38% between 2024 and 2029, and has the potential to reduce production costs by almost 20% in the agriculture sector.

Given that the global bakery and snacks sectors are substantial - estimated at $ 536.4 billion and $1.450 billion, respectively, in 2023 - both are poised to benefit from AI-driven innovations, reshaping everything from product development and production processes to marketing strategies and consumer engagement. “AI streamlines the entire production process while giving operators a deeper understanding of the factory floor,” says Ian Hodgson, systems GM at Ishida.

Rethinking production

AI is improving efficiency and challenging traditional ways of working by honing in on production and supply chain optimisation. Once installed, AI systems learn what the business considers normal and highlight any changes to that pattern. “With this knowledge, bakeries and snack manufacturers can improve their throughput and overall equipment effectiveness (OEE) through a single piece of software,” adds Hodgson.

Sorting machines innovator and post-harvest food solutions provider Tomra Food uses AI-driven sorting, grading and packing solutions to improve efficiency and lower waste in food production. Japanese food equipment and software leader Ishida has launched a remote production system incorporating advanced AI capabilities to enable production monitoring and better decisionmaking.

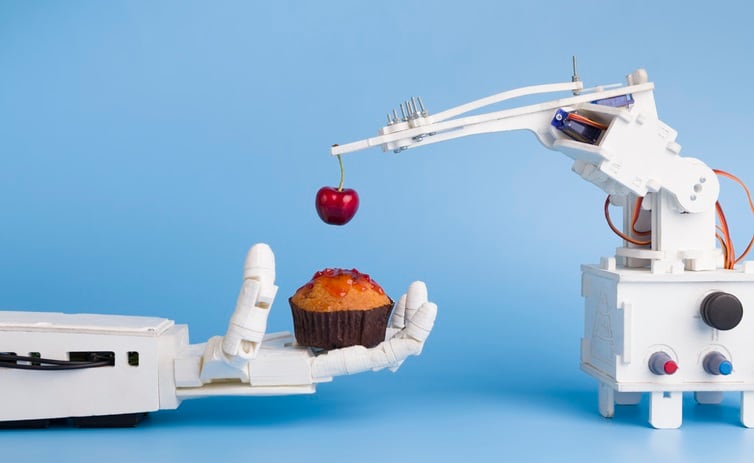

Food manufacturers are implementing AI with automation to elevate the benefits of the two technologies. One perhaps surprising advantage of introducing these into the production environment is that they can maintain the handcrafted quality and creativity that consumers expect from their finished food products.

Namely, AI and automation can maintain consistent product quality. “The software will notify businesses if an error on the production line impacts standards, such as the oven being too warm or machines dispensing too many ingredients,” says Hodgson. Food managers can then quickly correct any potential issue to ensure consumers enjoy a high-quality product.

While AI systems are integrated into bakery and snack production lines, they will evolve to fully understand what the business considers standard practice and suggest ways to optimise throughput. “This modification will allow businesses to further improve their way of working, generating more product and increasing revenue,” Hodgson adds.

Ramping up innovation

AI is also extending beyond the manufacturing environment to product development.

For example, European premium sweet bakery manufacturer Mademoiselle Desserts has partnered with F&B AI platform Tastewise to develop AI-generated flavour combinations, resulting in the launch of Blackberry & Mascarpone Cake.

Meanwhile, Mondelēz International uses AI to help design recipes faster and more precisely. The snacking giant has used AI to help craft 70 new products, including its Gluten-Free Golden Oreo.

AI is also enabling brands to maximise flavour. Bakery, patisserie and chocolate industry leader Puratos uses AI to analyse consumer trends and assist pâtissiers in crafting new flavour profiles and aesthetic designs. Italian ice cream creator Terra Gelateria is pioneering AI-generated flavours such as white chocolate with balsamic berries & black pepper to tap into consumers’ eclectic taste interests.

“The next step is for bakery and snack businesses to embrace the AI revolution and recognise the benefits it could have for their company,” says Hodgson.

Fears around AI development

While AI has the potential to advance organisations in various ways - from quality control to generating more profit and even enhancing marketing strategies and consumer engagement - it does stir up some insecurity. A leading fear around the uptake of the technology is that AI-driven efficiency will lead to job losses. However, says Hodgson, implementing AI has the potential to create new opportunities in research and development (R&D) and heighten tech-driven food production, as the software can oversee every aspect of the production line while it’s active. “Although it can notice issues a lot quicker than an operator, people will still be required to OEE, meaning jobs will not be at risk if AI is integrated into a business,” he adds.

Regulatory uncertainty is also a prominent issue affecting the more expansive food production and supply chain landscape. A shift in legal requirements has the power to influence AI-powered food development. The UK, for example, has yet to establish general statutory regulations for AI, but government has published guidance, highlighting safety and security.

“In the future, we may see official regulation, but the government has stated it aims to take a ‘pro-innovation’ approach, allowing food manufacturers to harness its potential for their production lines and supply chain,” Hodgson shares.

Study:

Vilhouphrenuo Zatsu, Angel Elizabeth Shine, et al. Revolutionizing the food industry: The transformative power of artificial intelligence-a review, Food Chemistry: X, Volume 24, 2024, 101867, doi.org/10.1016/j.fochx.2024.101867.